Why Regal Considers Customer Service Critical

April 24, 2019

What to Look for in a Metal Detector Test

June 6, 2019What’s New With The Food Safety Guidelines

Food safety guidelines can sometimes take a prominent position in the headlines lately. And even major meat and poultry companies can face major recall issues. Problems like these potentially costing millions of dollars and eroding consumer confidence. So it’s no wonder that these companies are taking this problem seriously. The government is also taking notice, with the USDA recently issuing updated guidelines for food safety. The overall goal is to streamline the process of reporting and addressing consumer complaints to prevent widespread contamination.

Determining Standards

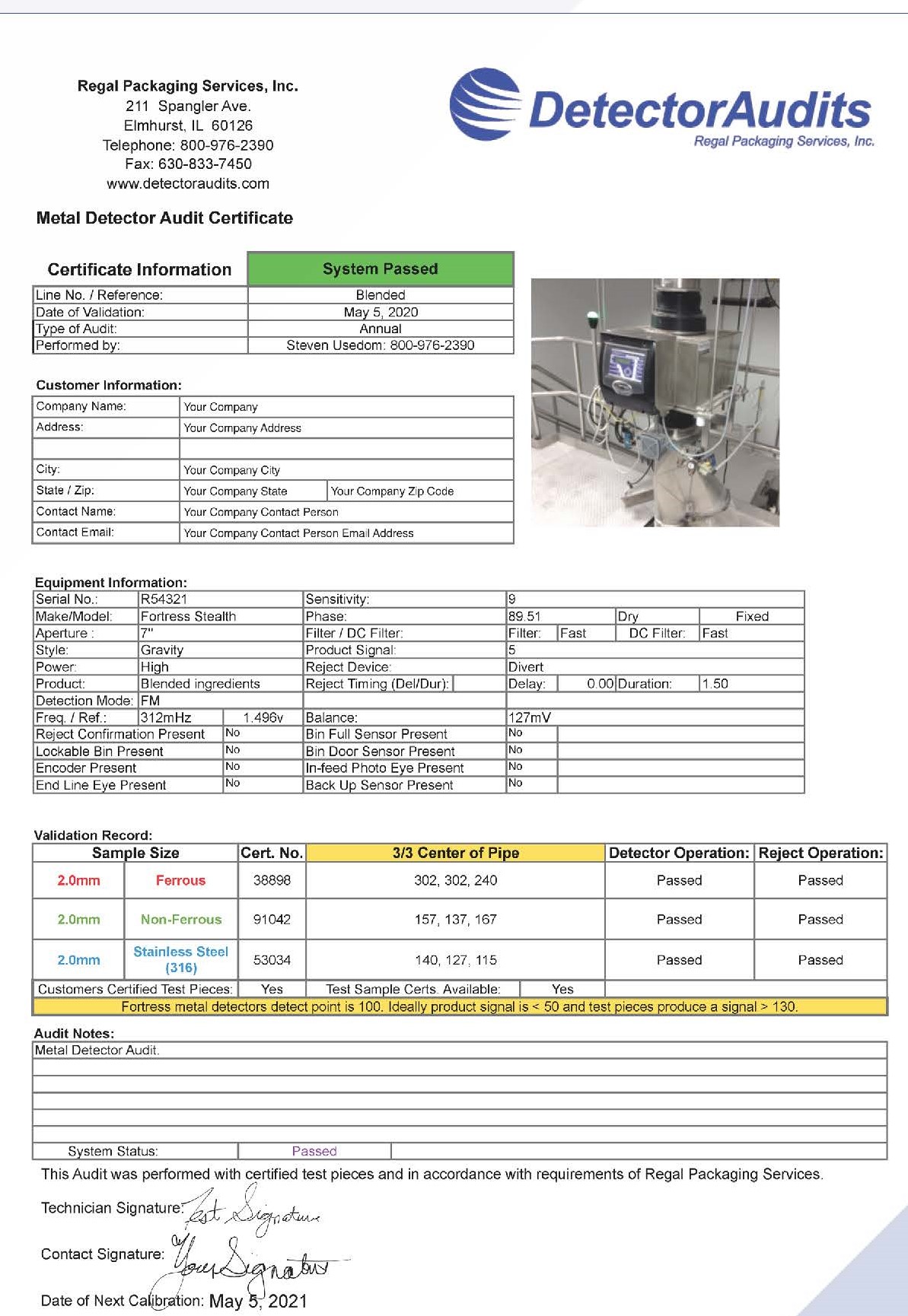

Of course, most food companies implement their own in house safety standards. These include the use of metal detectors to ensure that their products are free of any contaminants. Unfortunately, with regular use, over time, the very detectors that are supposed to be ensuring safety can become a part of the problem. They should be carefully monitored and regularly audited. In order to avoid this kind of problem, using quality, certified metal detector test rods demonstrate that your equipment is functioning properly. It will also help keep your products free of contamination. The newly updated food safety guidelines are aimed, for most part, at limiting the impact of existing recalls. This is done by encouraging manufacturers to take consumer complaints seriously and report them to the USDA within twenty-four hours. This can help to prevent a more widespread health issue. It just makes sense to avoid problems by ensuring the safety of all products from the beginning of the process. Fortunately, the method for doing so is relatively straightforward and it only requires the use of specially designed test samples. Test pieces, (rods, spheres, custom, etc.), can be used to test the proper function of a metal detector. If a machine works as it is intended, it will detect the presence of the test sample. Consequently, the system rejects product before it reaches the end of the automated process. Using a set of ferrous, non-Ferrous and stainless steel 316 metals makes a thorough testing process and improves safety dramatically. This allows for compliance to food safety guidelines.

Regal’s Experience

Regal Packaging is well aware of the importance of following food safety guidelines. That’s why we produce a wide range of high quality metal detector test standards to accommodate different types of detectors. They are available in a number of shapes, including spheres, rods and laminate, acetal and thermoform cards. And our test samples are made with ferrous (chrome steel), non-ferrous (brass) or stainless steel 316. X-ray inspection test pieces also include aluminum, soda-lime glass and ceramic (ZR02 and AL203), acetal, teflon and rubber. This provides the widest variety so that they’ll work with all types of metal detectors and x-ray inspection systems.

Stainless steel 316 is particularly important for testing as it has non-magnetic properties that make it difficult to detect. That means a detector picking up stainless steel 316 it should have no problem picking up other types of metal. This, combined with the fact that these pieces are designed not to degrade, makes them the best choice for ensuring the accuracy of your detectors and the safety of your products. Regal Packaging Certificates of Compliance are offered complimentary and without expiration.

Government

With both the USDA and the FDA recently upgrading their food safety guidelines in response to the increase in recalls, the importance of product testing is more significant than ever. The government is taking steps to tighten control over products imported from other countries as well as expediting the reporting process for consumer complaints, but it remains the responsibility of individual companies to implement regular testing practices and ensure the function of their metal detectors. Regal Packaging, Inc. understands how important safety is to companies and consumers alike, which is why each test piece we manufacture is certified for the life of the test piece and produced to meet the customer’s exact specifications. Food safety is so incredibly important that the government is stepping up its approach with tighter guidelines, and quality test samples from Regal Packaging can help you do your part as well.