4 Critical Principles of Metal Detection

July 1, 2023

Quality Assurance and Quality Control

September 1, 2023 Understanding Ceramics and X-ray

Understanding Ceramics and X-ray

One of the common contaminants companies are looking to remove from a product is ceramics. At Testrods.com we offer two types – AL203 and ZrO2.

AL203 stands for Alumina Oxide. “Aluminum Oxide (Al2O3), often abbreviated as Alumina, is one of the most popular fine ceramic material families worldwide. Encompassing a range of grades – characterized primarily by purity – coarse and dense alumina is renowned as one of the greatest materials in terms of price-to-performance ratios. Aluminum Oxide ceramics can subsequently service one of the broadest industrial cross-sections of any oxide ceramic on the market.”1

ZrO2 stands for Zirconia Oxide (or just “Zirconia”). “Zirconia (ZrO2) is unique among the fine ceramic oxide group due to its exceptional fracture toughness and thermal expansion properties. As a result, zirconia ceramics are widely used as a specialist solution in hard-wearing and high temperature applications. ZrO2 ceramics come in a range of grades and formats to satisfy the extreme requirements of these demanding markets.”2

In X-ray inspection systems, it is always critical to know the density of the material you’re hoping to find and reject. Since x-ray inspection is based on product density, you’ll need to understand the density of the expected contaminant. In a nutshell, considering that water has a density of 1.0g/cm3, you can expect that anything with lower density (anything that floats) will be extremely difficult to find.

- AL203 has a density of 3.9g/cm3, while

- ZrO2 has a density of 6.0g/cm3

It might even be worth an investment in a densitometer to determine which kind of ceramic contaminant test piece you should be using in daily testing. Without that knowledge, you may be completely missing the type of ceramic you’re hoping to capture. For instance, if you choose to use ZrO2, you are not likely to capture the AL230, which is less dense.

To “play it safe,” you may want to use the less dense AL203 so you are certain to capture the greater density ZrO2. That may mean, however, that you get false rejects based on the density of your product. Having the specific numbers at hand (determined by a densitometer) would be very helpful. And while a good densitometer can be an investment of thousands of dollars, it may be the best investment you make in quality assurance.

“Alumina Ceramic (AL203) is the most widely used fine ceramics material. This material has superb material characteristics such as high electrical insulation, high mechanical strength, high wear and chemical resistance.”3 In fact, it is “used in the following areas, among others: Heavy-duty forming tools, substrates and resistor cores in the electronics industry, tiles for wear protection, thread guides in textile engineering, seal and regulator discs for water taps and valves, heat-sinks, protection tubes in thermal processes or catalyst carriers for the chemicals industry.”4

ZrO2 is used for “has the highest strength and toughness at room temperature of all the advanced ceramic materials. The fine grain size allows for extremely smooth surfaces and sharp edges. Applications include scissors, knifes, slitters, pump shafts, metal-forming tools, fixtures, tweezers, wire drawing rings, bearing sleeves and valves.”5

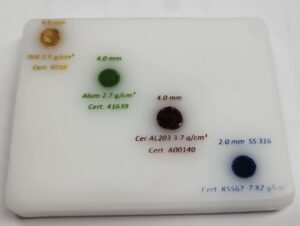

So given the wide range of applications for these 2 ceramics, you can expect that one of these or both should be in your cadre of ceramic test pieces. X-ray inspection, at times, seems to be as much of an art as it is a science. That is why getting all the statistical information you can is important to your approach and setting the demands of your HACCP plan. A solid quality assurance team, using the right equipment and understanding the right contaminant test piece can be the best means of protecting your consumer and your profit as well. Here’s a list of the contaminants we offer and their densities:

- POLY-PROPYLENE 0.9 g/cm3

- NYLON 1.1 g/cm3

- RUBBER – EPDM 1.14 g/cm3

- RUBBER – BUNA 1.2 g/cm3

- PVC 1.41 g/cm3

- DELRIN 1.42 g/cm3

- RUBBER – VITON 1.85 g/cm3

- TEFLON 2.2 g/cm3

- QUARTZ 2.2 g/cm3[/one_second]

- BOROSILICATE GLASS 2.23 g/cm3

- SODA-LIME GLASS 2.5 g/cm3

- ALUM 2.7 g/cm3

- ALUM (BONE) 2.7 g/cm3

- CER (AL203) 3.7 g/cm3

- CER (ZRO2) 5.6 g/cm3

- SS 316 7.82 g/cm3

- FERROUS 7.85 g/cm3

- NON-FERROUS 8.48 g/cm3

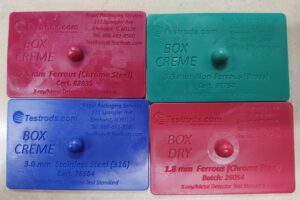

As you develop your Food Safety Plan, consider what types of contaminant you may want on a card or in a test piece. Many of our customers choose to buy a multi-card. We offer cards with whatever type contaminant (above) you need in a host of sizes. Our most common card is a thermoform version with 24 contaminants comprised of:

- 0.6, 0.7, 0.8, 1.0, 1.2, 1.5mm Stainless Steel 316 –

- 2.0, 3.0, 4.0, 5.0, 6.0, 8.0mm Ceramic ZRO2 –

- 2.0, 3.0, 4.0, 5.0, 6.0, 7.0mm Soda-Lime Glass –

- 3.0, 4.0, 5.0, 6.0, 7.0, 8.0mm Rubber

We have manufactured cards with as many as 100 contaminants, and you can design your own card based on the needs of your product, your production line, your HACCP plan and any regulations that apply to your company.

We’re here to help you ensure that your product, the one you put in the marketplace, is as safe as possible. We consider ourselves an extension of your food safety program. Contact us at: (866) 691-8560 or email testrods@testrods.com or order online here at testrods.com.