What Makes Metal Detection in the Food Industry Different?

May 12, 2021

Calibration and Verification

March 10, 2021Product Effect and Metal Detection

Setting up a metal detector for use on a food production line requires an understanding of “product effect.” You may need a little help understanding the ins and outs of the process.

What is it?

This is the magnetic and conductive properties of a product. Whether frozen, liquid, solid or powder, the product will have some effect on the coils inside the aperture of the detector. After factoring this in, metal detectors must “eliminate” it or ignore it. This process should be cared for during setup, AND on a regularly scheduled basis. This is especially true when a new batch of product is run or during a shift change. In a manner of speaking, the detector needs to “learn” what is the product effect and any interference in the surrounding environment. The detector will naturally discover these properties. Thus, you can set a baseline for production. This is a setting in which the clean product and it’s container moves through the detector without setting off the reject device.

When working to determine and resolve the effect of the product, keep these things in mind:

1) It is not physically possible to detect any contaminant whose value is smaller than the Product Effect value. For instance, if the effect is equal to metal the size of a ping pong ball, you will not be to achieve a contaminant the size of a marble. Metal detectors are made to set the reject point at a specific threshold. They rely on the simple mathematical formula:

Sensitivity Setting + Product Effect + Contaminant Value = Reject Alarm

In an ideal scenario, the Sensitivity Setting and Product Effect should be just below the Reject Alarm threshold. This means even the smallest contaminant can be detected. Fluctuations in the Effect can create an undesired “gray area.” To avoid a false positive (the largest portion the gray area), the Sensitivity Setting will have to be lower. But this in turn requires the Contaminant Value to be larger in order to have consistent detection.

2) The larger the deviation in Product Effect, the less sensitive your detector will be.

The orientation of the product in the aperture can also alter Effect the product has on the system. Imagine the difference between throwing a pebble in a glass smooth lake and doing a cannonball off the dock. The splash is the Product Effect. Upon entering the magnetic field of the detector, the product creates a ‘splash’ in the field. Metal detectors function on a balanced field principle. Thus, the ‘splash’ determines whether a detector is seeing product effect, or is adding the effect AND contaminant together.

3) Always run the product which will create the worst-case product effect value to avoid a false positive and reject.

4) Consider the condition of the product. A frozen product that is only partially frozen will affect your values considerably. The more frozen your product is, the lower the Product Effect value will be and the greater your sensitivity will be. That is, it will behave more like a dry product. Higher temperature products, or hot products directly from processing, will always show greater product effect values because they contain moisture.

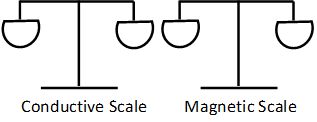

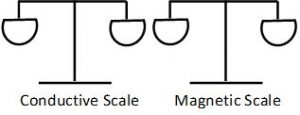

Product Effect and Phasing

The control electronics of a metal detector actually split the received signal into two separate channels: magnetic and conductive. This means there are essentially two balanced scales within the unit (figure 3). These scales constantly measure the magnetic and conductive components of every disturbance. Products that are being inspected can have one or both characteristics.

For example, any iron-enriched product, such as cereals, create a large magnetic interference that the detector must overcome to detect small pieces of metal. These are referred to as “dry” products. On the other hand, products with high moisture or salt content such as bread, meat, cheese, etc. are electrically conductive. They produce a conductive error signal and are referred to as “wet” products. The table below shows typical product error signals and categorizes them as wet or dry.

The detector must remove or reduce this “product effect” in order to identify a metal contaminant. Most modern detectors will have some form of automatic calibration to do this – it is often referred to a phasing.

| Typical ‘Wet’ Products | Typical ‘Dry’ Products |

|

Food: Meat, Cheese, Bread and Bakery Products, Fish, Dairy Products, Salads |

Food: Cereal, Crackers, Flour, Tablets Powders, Biscuits, Frozen Food Products ( < -1.0 Degrees C), Peanut Butter and Margarine (Vegetable oil is not conductive) |

| Packaging: Metalized Films | Other: Wood Products, Plastics and Rubber (Products with high carbon black content may be considered ‘wet’), Textiles, Paper Products |

| Other: Plastic and Rubber products with high carbon black content |

|

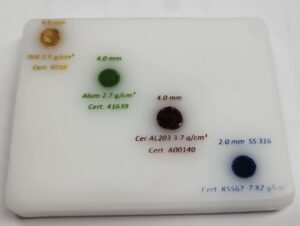

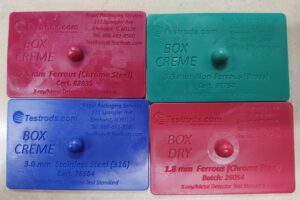

Need certified test pieces that will help accomplish what you need done in metal detection to satisfy your HACCP plan and food safety audit. Take a look here on the website, call us at 866-691-8560 or email testrods@testrods.com.