The Backbreaking Burden of Finding Bone

March 1, 2025

Can You Afford to Miss What We Offer for Food Safety?

May 1, 2025 How Do You Test a Pipeline System?

How Do You Test a Pipeline System?

Metal detectors used with product carried in a pipeline are used commonly in food processing. They are useful in inspecting larger quantities of pumped soft, semi-liquid and liquid products, such as dairy, including: cream, yogurt, butter, soft cheeses. In addition, they well with some meats and pet food.

As you might expect, a pipeline system adds a bit of complexity to the testing of a process line because it is a fully enclosed system. It’s difficult to test the reject device since, ideally, you need to insert a test piece into this closed system. In most cases, this would create cleanliness and sanitation concerns as well as the need to find a way to retrieve the test piece. Done manually, the process can be messy, increasing testing times from several minutes to 15 minutes or more. Moreover, this can be a significant strain on resources as well as a interruption to production. And finally, this practice amplifies the risk of contaminating the product.

The typical way to test the pipeline system throughout the daily process is to use a product like our flexible test whips (sometimes referred to as a “pipeline rod” or “flexible rod”).

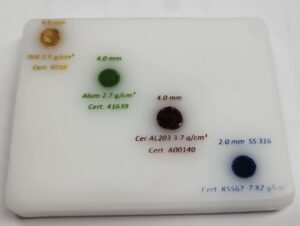

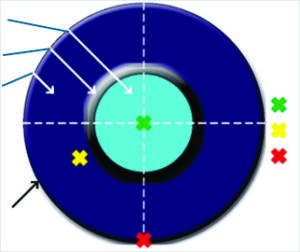

The metal in these test whips is sized (as with all test pieces) appropriate to the application. The testing normally takes place on the side of the pipe, between the pipe and the metal detector aperture (see diagram below). The metal size is generally pro-rated to the center of the aperture, which is the least sensitive point of the detector. In other words, because the test piece is closer to the wall of the aperture, it will be easier to detect, so a smaller size metal should be used.

You may (and probably should) have two different test pieces for a pipeline system. The first would be the one used for daily and hourly testing on the side of the pipe. But periodically you could insert a test ball into the process and watch it get rejected from the system. So, a pipeline system should be tested side of pipe (pro-rated size test pieces) and a periodical introduction of a test piece (usually a ball) into the process to verify the reject timing is correct.

Get What You Need

You can purchase the highest quality, certified test whips when you shop now at Testrods.com. In addition to this type test piece, here at Regal Packaging Services, we also make customized solutions for our customers. In the case of an overhead system, you may not be able to reach the aperture with a flexible whip. You could, however, reach the overhead location with a rigid test piece. We’ve custom manufactured test pieces from 24 inches all the way up to 72 inches, but that’s not the limit. We can even put a flexible end on that rigid test piece if needed. Call us at 866-691-8560 or email testrods@testrods.com.

| Product

Product Pipe Gap between

Aperture |

|

Least sensitive aperture pt. Common test point Most sensitive aperture pt. |