Down to the Basics

July 8, 2020

Types and Sizes of Metals

October 22, 2020Custom Test Pieces

Imagine for a moment that your production line involves an overhead gravity feed metal detector. Your HACCP plan calls for regular, hourly testing to ensure food safety. But your operator has to climb significantly steep set of stairs. Certainly, there are measures that can be taken to protect the operator’s safety, right? But why not design a testing system that can be done from the ground. Sound plausible? Well that’s exactly what one of our customers asked us to do. Custom test pieces are our specialty.

Innovation

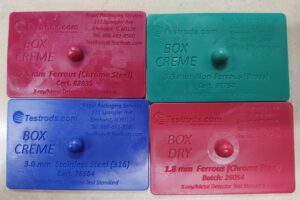

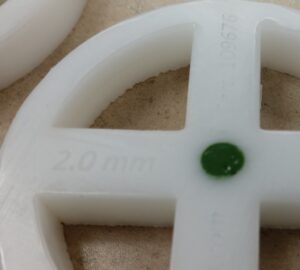

With a little time and ingenuity, we were able to meet the demand. Using the flexible material we use for our 20” Testwhips, we put together a 20 foot “rope” with an open end. The rope consisted of 3 sections: 1 red (Ferrous), 1 green (non-ferrous) and 1 blue (stainless steel 316). Each length was just under 7 feet in length, with the appropriate ball in the end. The ends were then joined together. After feeding the rope through the metal detector and a loop above the detector, the customer then bonded together the last joint. Now, standing on the ground, the operator can feed the entire rope through the system,. The testing is done for all 3 types of metal. The rope is simply pulled to the side when not in use at a section where there is no metal.

Or maybe you need a test piece shaped exactly like your product. You want to use it in a tray as if it were an actual product. We have designed and manufactured several, including one that mirrored the unique shape of a specialty ice cream bar. Then again, your test piece may need to be small. It needs to fit in a vacuum tube where it will be cycled through several detectors in quick shot test. Perhaps it should be shaped like an octagon or a cube or have a pointed end to be inserted into a bagged product. At Testrods.com, nothing limits the design possibilities.

Challenge Us

There isn’t a challenge yet that we haven’t been able to meet for custom test pieces. But it’s not just about meeting a challenge. Certainly, it’s fun to solve a food line riddle, so to speak. More importantly, however, we take great satisfaction in helping our customers find the simplest, most efficient and effective means of keeping their product safe. It’s the driving force behind everything we do.

At Regal Packaging Services, we’re not just selling or servicing Fortress Technology metal detectors. And we’re not just providing Audit Services to any metal detector or x-ray inspection system you might have. We want you to have complete confidence that you’re meeting the stringent demands of our HACCP plan and the pressures of the marketplace. And we know that sometimes requires quality, certified custom test pieces.

We’re Shoppers, Too!

After all, we’re not only in the business of supplying technology in the food industry, we’re also customers at the grocery store. When I pick up a can of soup or a box of cereal, I want to have confidence in the manufacturer of the product. I want to know that when I sit down at the dinner table with my family, I won’t have to think about biting down on a chunk of metal or some other contaminant.

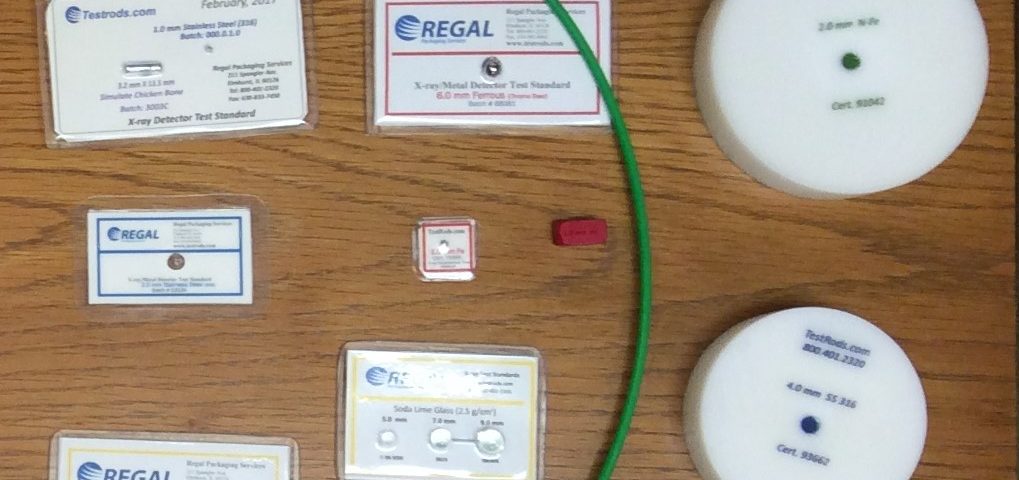

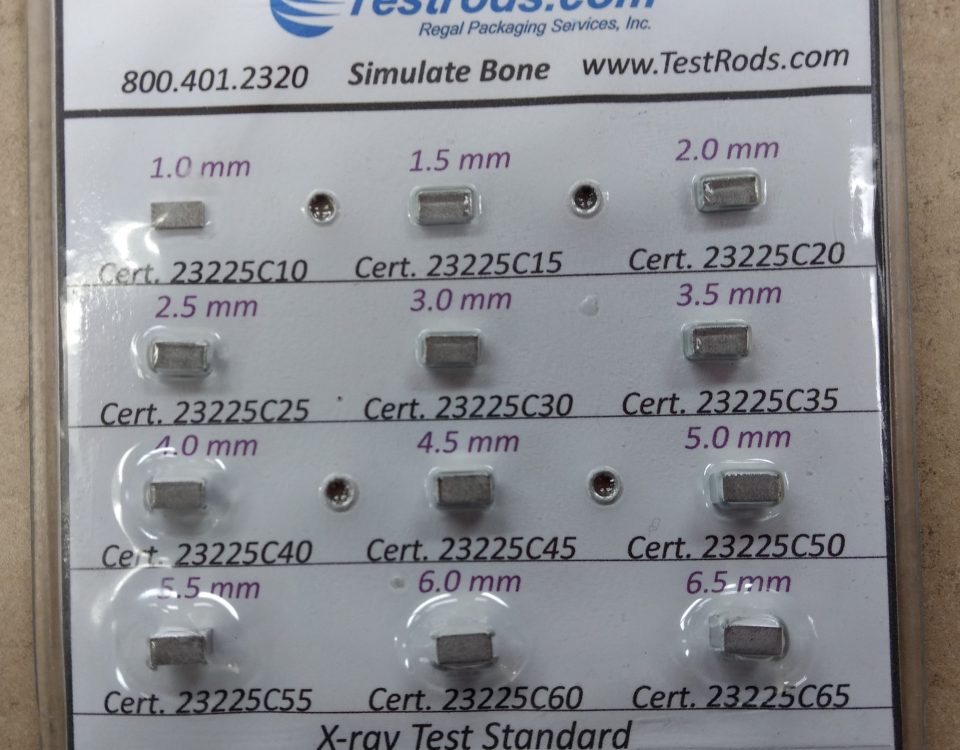

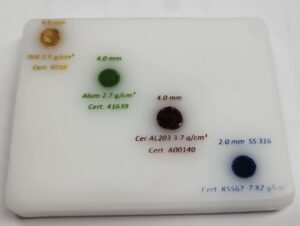

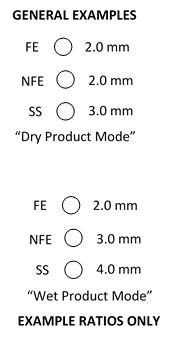

Testrods.com offers a wide variety of sizes and contaminant types, including Ferrous (Chrome Steel), Non-Ferrous (Brass), Stainless Steel 316, Aluminum, Soda-Lime Glass, Ceramic, PTFE (Teflon), Acetal (Delrin) and Rubber.

No matter the size, shape or weight of test piece you need, give us a call at 866-691-8560 or email testrods@testrods.com and we’ll provide the solution for your custom test pieces.