Guide To Metal Detector Verification

July 4, 2019

What Are Metal Detector Test Standards?

July 11, 2019Gravity Fed, Conveyer Fed vs. Pipeline Metal Detection Systems Test Pieces

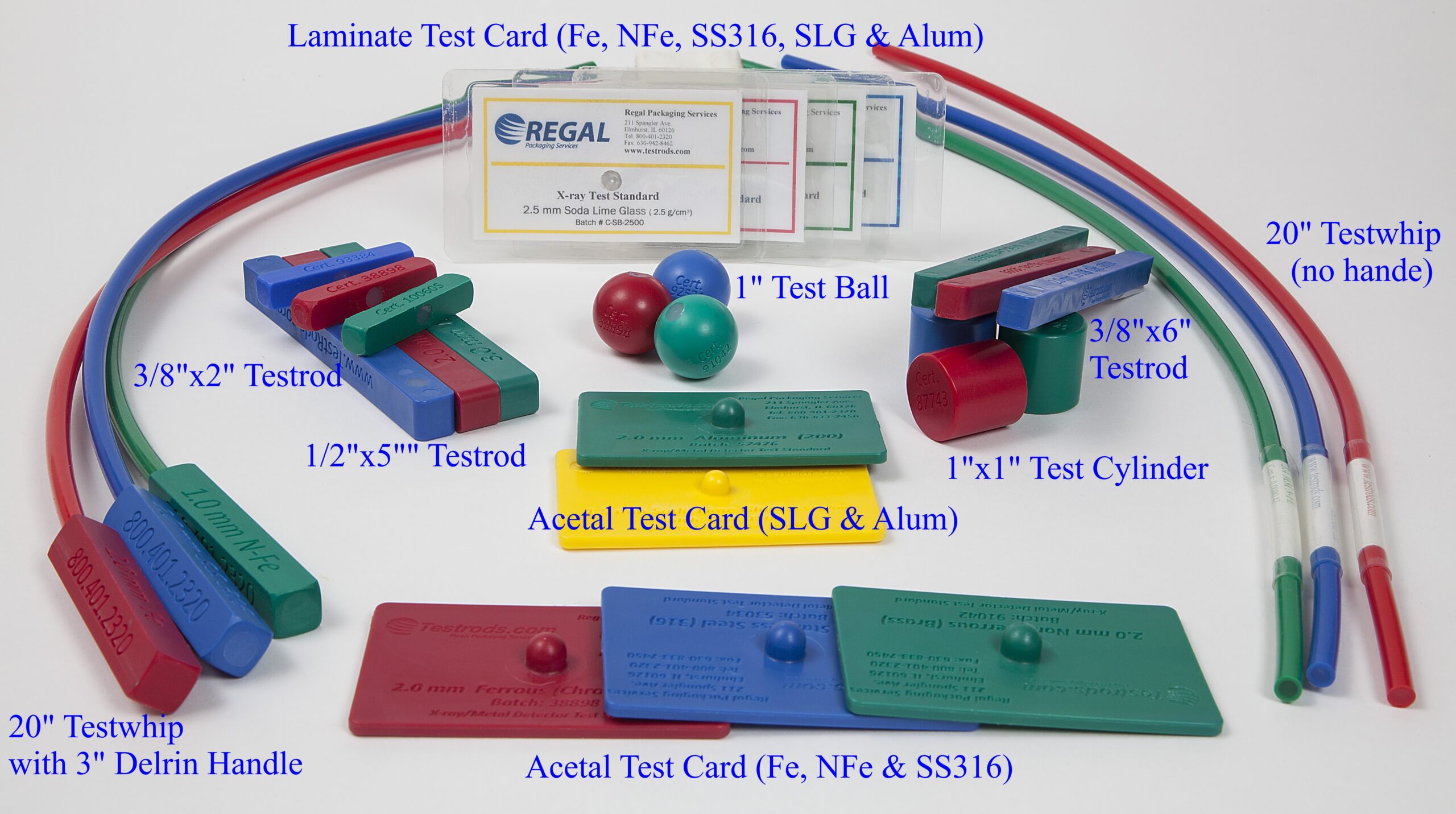

Metal detection systems test pieces are a crucial part of any food industry production line. These small pieces can help ensure that your metal detection system is functioning properly and your products are reaching customers safely. The specific type of piece you use will depend on a number of factors including the kind of detector system you have and the size and makeup of your product.

Three Types

There are three basic types of detector systems: gravity fed, conveyer fed and pipeline. Each has its own specific method of operation and, consequently, requires a unique approach to testing. In general, testing involves sending test pieces of ferrous, non-ferrous and stainless steel through the production line. This ensures that the detector responds properly and automatically rejects potential metal contaminants.

Conveyer fed systems move packaged products through the detector by means of a conveyor belt. Because these systems can handle products already in their final packaging, they can be more easily tested using sample packs. Metal detection systems test pieces in these instances can be cards, rods or sticks. They can also be incorporated comfortably within, or attached to, the test sample or packaged.

Gravity fed systems use a series of pipes/chutes stacked vertically, enabling the natural flow of gravity to move the product. These systems are used most commonly for dry, free flowing products. These can be grains, flours, cereals, rice, nuts and sugar as well as vertical packaging of liquids, pastes and slurries. Smaller test pieces can be inserted into the product stream provided they can pass smoothly through the detector aperture.

In pipeline systems, a section of non-metallic pipe is used to pass liquid, slurry or paste products through the detector. These systems are used for sauces, dairy products, juices, sausage and other meat products. In this case, the metal detection systems test pieces used would have to be quite small. They need to fit through the piping, or, slim test pipes can be used between the pipe and the detector head.

Your Application Determines

Whichever type of detector you use, having strict testing procedures in place is extremely important. Tests should be conducted at regular intervals, usually hourly or at least at shift changes and between different products. The more often your detectors are tested, the more easily you can identify and correct problems and avoid potential contamination. And you’ll need test pieces certified by NIST standards and approved for food grade contact.

With these standards in mind, Regal Packaging Services, Inc. provides high quality metal detection systems test pieces for all types of systems. We work with each customer to design pieces for their particular system and offer a wide range of materials and shapes. Each individual piece is certified to guarantee quality and durability so that you can count on getting the most accurate results with each test.

You can’t afford to take chances when it comes to the quality of your products and that means using the best possible metal detector system. With Regal Packaging Services test pieces you’ll be able to keep your metal detection system working properly so that your customers will have products they can rely on.