Compare Food Grade Metal Detectors

June 20, 2019

Tips for Metal Detection Testing

June 27, 2019 Using Metal Detector Test Pieces

Using Metal Detector Test Pieces

Metal detector test pieces are the measuring stick that food and packaging industry companies use to maintain safe metal detection systems. The presence of even a single contaminant in a batch of products could cost a company millions of dollars. It could also mean the loss of confidence of their customers. It is essential, then, that companies do everything in their power to ensure the safety of their products.

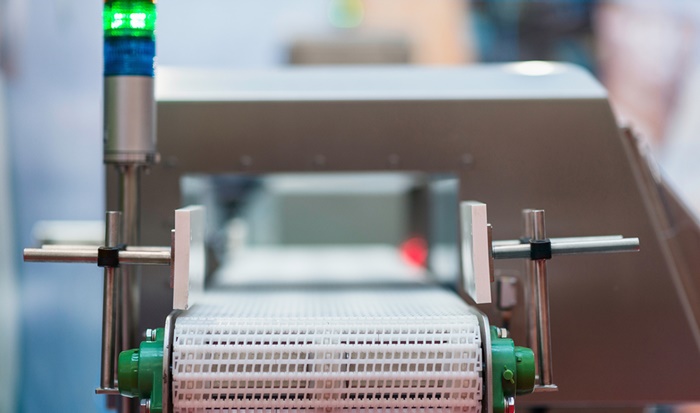

Using a metal detector is the most foolproof way of staying on top of product integrity. The detector is the most immediate indication of the presence of any type of contaminant. Of course, that safety process is only as good as the detector itself. This is why test standards should be used to ensure the proper function of all detectors. Using test samples is a quick, easy way to determine the proper function of your metal detector. And it helps keep your products free of contamination.

What we do

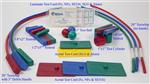

At Regal, we produce Metal detector test pieces in a variety of shapes and sizes to accommodate different detectors. We have spheres, rods, cards and more, each engraved with its own unique certification number. Our products are made in ferrous (chrome steel), non-ferrous (brass) or stainless steel 316. We also offer aluminum, soda lime glass, ceramic (ZR02 and AL203), acetal, teflon (PTFE) and .

In order to ensure product safety, it is necessary to use three different types of metal detector test samples. Tuning drift might make it easier to detect one type of metal rather than another. Additionally, all three metals may be present on your production line. Using all three is standard in the industry. It is important for thorough testing and provides the confidence you want in your systems. This way you’ll know that as each item is scanned and a foreign substance is found, the entire product isn’t rejected. You need to know that nothing with contaminant ends up on store shelves.

Position

When using Metal detector test pieces it is recommended that you position them so that they will pass through the center of the aperture. This is the least sensitive position inside any metal detector. If a test piece can be detected in this position, then it is should be detected in any other part of the detector head. This way you can be sure that your detector is operating accurately at every point.

The use of stainless steel 316 in metal detector test pieces is particularly important. Its non-magnetic properties make it particularly difficult to detect, making it the industry standard. If your detector can find test pieces made with stainless steel 316 then it should easily detect other types. If you’re using SS 304 or another grade stainless steel in your test pieces, you may be missing other types.

The Regal difference

Our test pieces are designed not to degrade, making them durable under constant use and maintain certification standards. This is paramount. Detectors should be tested as frequently as once an hour to maintain a high level of safety. A good auditor will want to know the proper certifications are met.

That’s why Regal goes to such great lengths to provide top quality Metal detector test pieces. Your equipment should function effectively, which is why each piece we produce is manufactured with care and certified for life.

We also understand that machinery can vary widely. Each company may have its own specific needs, so we’ll work with you to make the exact pieces you require. Whether you need a 24ft “rope” or a 1/2” x 3/16” “pill,” we can design and manufacture it to meet your challenge.

The safety of your products and your customers is too valuable to take lightly, so when you’re looking for metal detector test pieces you can rely on, make sure you go to the industry leader, Regal Packaging Services, Inc. That way you’ll know you’re getting the very best.