You Can Trust ISO Certification

May 1, 2024

The People Behind the Metrics of Quality Control

July 1, 2024 Stones

Stones

Stones, without question, present a real hazard in the overall food safety picture. While stones may not be a biohazard, biting down a stone could be traumatic. “When a small pebble ends up in your food, instead of enjoying a simple snack, you may end up at the dentist or emergency room.”1 Even worse, “It’s possible that people may even need surgery to remove a stone after ingesting it.” 1

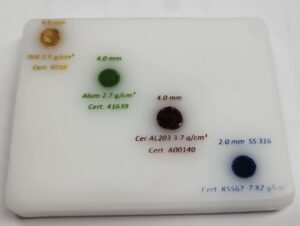

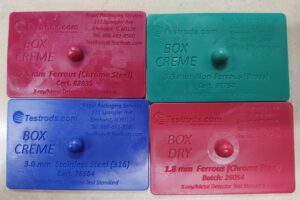

To provide every reasonable, certifiable contaminant type, the Testrods Division of Regal Packaging Services offers 16 different variations in a wide range of sizes. Each of these contaminants was chosen based on the needs within the food and other industries as well as our ability to source certifiable sources. These contaminants consist of:

- Polypropylene (0.9 g/cm3): 4.0, 4.8, 5.6, 6.4, 7.9, 9.5mm

- Nylon (1.1 g/cm3): 4.0, 4.8, 7.9mm

- EPDM Rubber (1.14 g/cm3): 6.4, 7.9mm

- Buna Rubber (1.2 g/cm3): 1.6, 2.4, 3.0, 4.0, 5.0, 6.0, 7.0, 8.0, 9.0, 9.5, 12.7mm

- Acetal (Delrin) (1.4 g/cm3): 2.4, 3.2, 4.8, 5.6, 6.4, 7.9, 9.5, 11.1, 12.7, 15.9, 19.1, 25.4mm

- Viton Rubber (1.85 g/cm3): 4, 3.2, 4.0, 4.8, 5.6, 6.4mm

- PTFE (Teflon) (2.2 g/cm3): 0.8, 1.6, 2.4, 3.2, 4.8, 5.6, 6.4, 7.9, 9.5, 11.1, 12.7, 14.3, 15.9, 19.1, 25.4mm

- Quartz (2.2g/cm3): 2.0, 3.0, 4.0, 5.0. 6.0, 7.0 and 8.0mm

- Soda-Lime Glass (2.5 g/cm3): 0.7, 0.8, 0.9, 1.0, 1.5, 2.0, 2.5, 3.0, 3.5, 4.0, 4.5, 5.0, 6.0, 7.0, 8.0, 9.0mm

- Aluminum (2.7 g/cm3): 0.8, 1.0, 1.2, 1.3, 1.4, 1.5, 2.0, 2.4, 2.5, 3.0, 3.5, 4.0, 4.8, 5.0, 6.0, 7.0, 8.0, 9.0, 10.0mm

- Ceramic AL203 (3.9 g/cm3): 1.0, 1.5, 2.0, 2.5, 3.0, 3.5, 4.0, 4.5, 5.0, 6.0mm

- Ceramic ZrO2 (6.0 g/cm3): 8, 1.0, 1.2, 1.5, 2.0, 2.4, 2.5, 3.0, 3.5, 4.0, 4.5, 5.0, 6.0, 7.0, 8.0, 9.5mm

- Stainless Steel 316 (7.82 g/cm3): 0.5, 0.6, 0.7, 0.8, 0.9, 1.0, 1.2, 1.4, 1.5, 1.6, 1.8, 2.0, 2.2, 2.4, 2.5, 2.6, 2.8, 3.0, 3.2, 3.5, 3.5, 3.6, 3.8, 4.0, 4.2, 4.4, 4.5, 4.6, 4.8, 5.0, 5.5, 6.0, 6.5, 7.0, 7.5, 8.0, 8.5, 9.0, 9.5mm

- Ferrous (Chrome Steel) (7.85 g/cm3): 0.5, 0.6, 0.7, 0.8, 0.9, 1.0, 1.2, 1.4, 1.5, 1.6, 1.8, 2.0, 2.2, 2.4, 2.5, 2.6, 2.8, 3.0, 3.2, 3.5, 3.5, 3.6, 3.8, 4.0, 4.2, 4.4, 4.5, 4.6, 4.8, 5.0, 5.5, 6.0, 6.5, 7.0, 7.5,

- 0, 8.5, 9.0, 9.5mm

- Non-Ferrous (Brass) (8.48 g/cm3): 0.5, 0.6, 0.7, 0.8, 0.9, 1.0, 1.2, 1.4, 1.5, 1.6, 1.8, 2.0, 2.2, 2.4, 2.5, 2.6, 2.8, 3.0, 3.2, 3.5, 3.5, 3.6, 3.8, 4.0, 4.2, 4.4, 4.5, 4.6, 4.8, 5.0, 5.5, 6.0, 6.5, 7.0, 7.5, 8.0, 8.5, 9.0, 9.5mm

All our contaminants are available in a variety of formats, and we also offer a small range of colored plastics which are used in Image Scanning Systems. Typically, when it comes to x-ray inspection, which is how stones can be detected, the preferred format is either a laminate or thermoform card. And, as you can see from the list above, the densities we offer range from 0.9g/cm3 all the way up to 8.48g/cm3, though non-ferrous (brass) is not ordinarily used for x-ray inspection.

Since x-ray contaminant detection and the search for stone are based on the principle of density, it’s important to determine what is the consistency of the impurity you’re trying to find. For a contaminant to show up on x-ray, it must have a higher density than the product being tested. In fact, there is a general saying about x-ray contaminant: “if it’s less dense than water (if it floats), you won’t find it.” Water is slightly less than 1.0g/cm3. So, if the contaminant you’re looking for is less than that, it’s unlikely that you’ll be able to reject it.

What we’re considering in this article is why Testrods does not offer stones as a standard contaminant. Stone, which is what we seem to call every kind of rock or mineral we see on the ground, has a plethora of variable attributes, not the least of which is density. Stones can range from 1.1g/cm3 (coal) 22.4g/cm3 (Iridium), which is rare, but it demonstrates the incredible variety of what you might find lying on the ground, sitting in a field, or ending up in a product. And this is where the difficulty lies in getting the stones out of your product or determining what density and/or size test piece you should use for regular testing.

That’s why we recommend that you begin the process with a multi-card having several different contaminants with aa diversity of sizes (see our custom product page). This way, it’s possible to compare the contaminant with the typical stones you’re working to find to see which type has the nearest appearance to your stones. Once a standard is determined, a single seed card can be used for regular testing. But we recognize that may not be the preferred comparison.

As an alternative then, we have offered customers the opportunity to send us samples of the stone which we safely encase in thermoform cards. Within a limited range, we can grind the stone down to the appropriate or expected size(s). At that point, we’re not able to certify the size, but we do certify the plastic container/card as food grade safe. What can be written into a HACCP plan is the criteria of testing with stone that matches the sample of stone from the original source. The intended end, of course, is the safety of the consumer.

The difficulty of detecting stones will last as long as food products are harvested from fields and other related sources. We’re trying to provide manufacturers and processors with the best tools possible to eradicate stones from the end-product. Call us at 866-691-8560 or email testrods@testrods.com for more information.