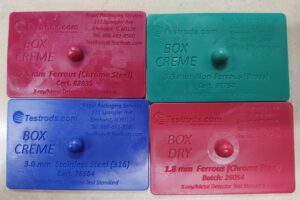

Metal Contaminant Types

October 1, 2021

Metal Detection Protocols and Practices

December 1, 2021X-Ray Contaminant Types

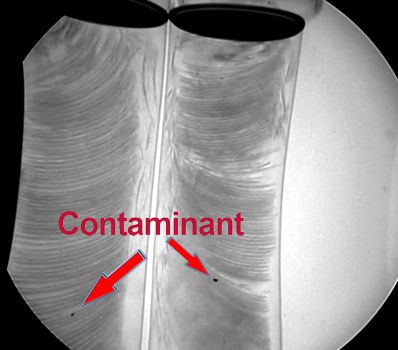

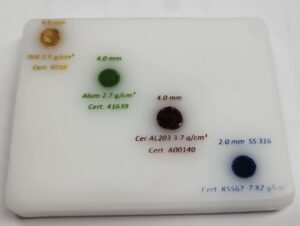

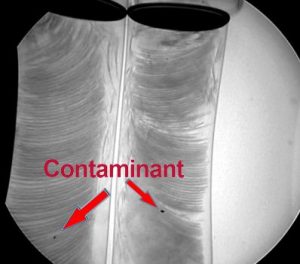

X-ray inspection in the food industry requires an understanding of the principles behind x-ray technology. Metal detection is based on the conductivity and magnetic properties of metal, but x-ray inspection is based on density. And the densities can range from 0.857 g/cm3 (polyethylene) to 7.82 g/cm3 (SS 316) and 8.48 g/cm3 (Non-Ferrous). That’s a pretty wide range of x-ray contaminant types!

X-ray inspection in the food industry requires an understanding of the principles behind x-ray technology. Metal detection is based on the conductivity and magnetic properties of metal, but x-ray inspection is based on density. And the densities can range from 0.857 g/cm3 (polyethylene) to 7.82 g/cm3 (SS 316) and 8.48 g/cm3 (Non-Ferrous). That’s a pretty wide range of x-ray contaminant types!

That means you need to know what plastic or metal (x-ray contaminant types) you’re looking for and what its density is. And you may not have the equipment onsite to determine the viscosity (density) of your potential contaminant. In addition, you’ll have to judge the difference between the density of your product and the contaminant. Some companies will tell you they can find any foreign substance or object in your product. That’s simply not true. Consider that if the density of your product is 1.59g/cm3 (sugar) and your contaminant is nitrile rubber (1.2 g/cm3). In that case, you won’t be able to detect the rubber no matter what your x-ray system or settings.

Will It Float

In general, the quick test is this: “If it floats, it’s not detectable.” In other words, if your x-ray contaminant type is less dense than water, 0.997 g/cm,3 then it’s not detectable. It’s the reason your skin and organs (for the most part) don’t show up under x-ray.

But that doesn’t mean you can’t detect anything. In that same sugar, you should be able to detect:

-

Polypropylene – 0.9g/cm3 (nearly impossible/less dense than water)

-

Nylon – 1.1 g/cm3

-

EPDM Rubber – 1.14 g/cm3

-

Acetal (Delrin) – 1.4 g/cm3

-

Buna Rubber – 1.33 g/cm3

-

Viton Rubber: – 1.85 g/cm3

-

PTFE 2.2 g/cm3

-

Quartz – 2.2g/cm3

-

Soda-Lime Glass 2.5 g/cm3

-

Aluminum 2.7 g/cm3

-

Ceramic (AL203) 3.7 g/cm3

-

Ceramic (ZRO2) 5.6 g/cm3

-

Stainless Steel 316 7.82 g/cm3

-

Ferrous 7.85 g/cm3

-

Non-Ferrous 8.48 g/cm3